Attributes

| Name | Value |

|---|---|

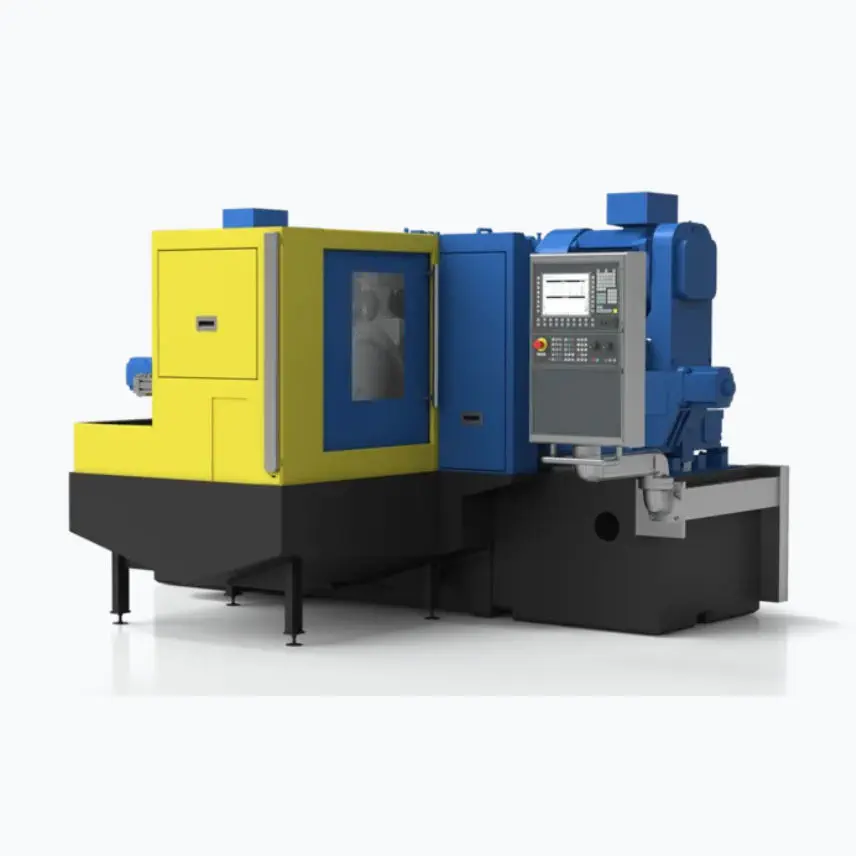

| Type | vertical disc |

| Applications | workpiece |

| Control type | CNC |

| Other characteristics | automated loading/unloading |

Description

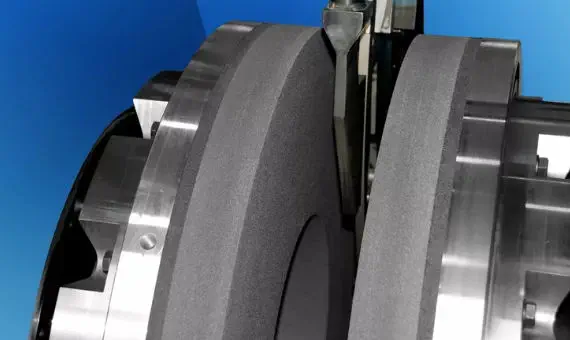

With SATURN double-wheel surface grinding, two vertical grinding wheels grind the workpiece simultaneously at its parallel end faces. With the through-feed grinding process, the grinding wheels are positioned slightly conically to each other so that the workpiece guided through the grinding zone has not reached its final dimension until it exits.

With SATURN plunge-cut grinding, the grinding wheels are arranged exactly parallel to each other. The workpiece carrier turns continuously at low speed. Both grinding wheels feed simultaneously until the final dimension is reached. Then the finish-ground workpiece is unloaded.

Highlights

High output

Automatic loading and unloading

Automatic measurement control

Long workpiece service life

Emulsion or oil as cooling lubricant

Simple grinding wheel change

Machine bed made of cast mineral

Automatic type detection

Equipment and Options

CONTROL SYSTEM

The Erwin Junker Operator Panel was specifically developed to control grinding machines. All machine components are controlled using the operator panel – irrespective of the series and the used control system. The identical structure, intuitive menu guidance and visualization of the workpiece geometry make for extreme user convenience and flexibility in operation. Programming takes place directly using the operator panel or an external programming tool.

MACHINE BED

The machine bed made of mineral cast provides impressive damping behavior and torsional rigidity. The temperature stability allows fluctuations in the ambient temperature to be compensated with a minimum of effort, ensuring a high level of dimensional stability throughout the whole day.

More from Erwin Junker Maschinenfabrik GmbH