Attributes

| Name | Value |

|---|---|

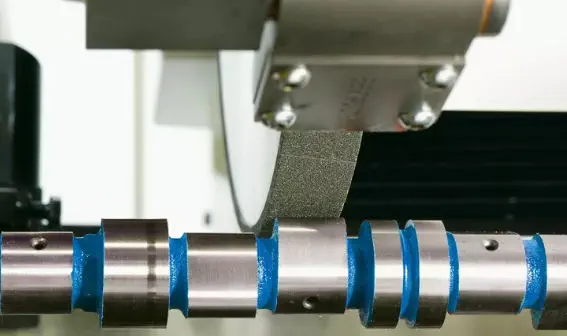

| Applications | workpiece, camshaft |

| Control type | CNC |

| Other characteristics | precision, high-performance, multi-spindle, high-capacity |

| Power | 42 kW(57.1 hp) |

Description

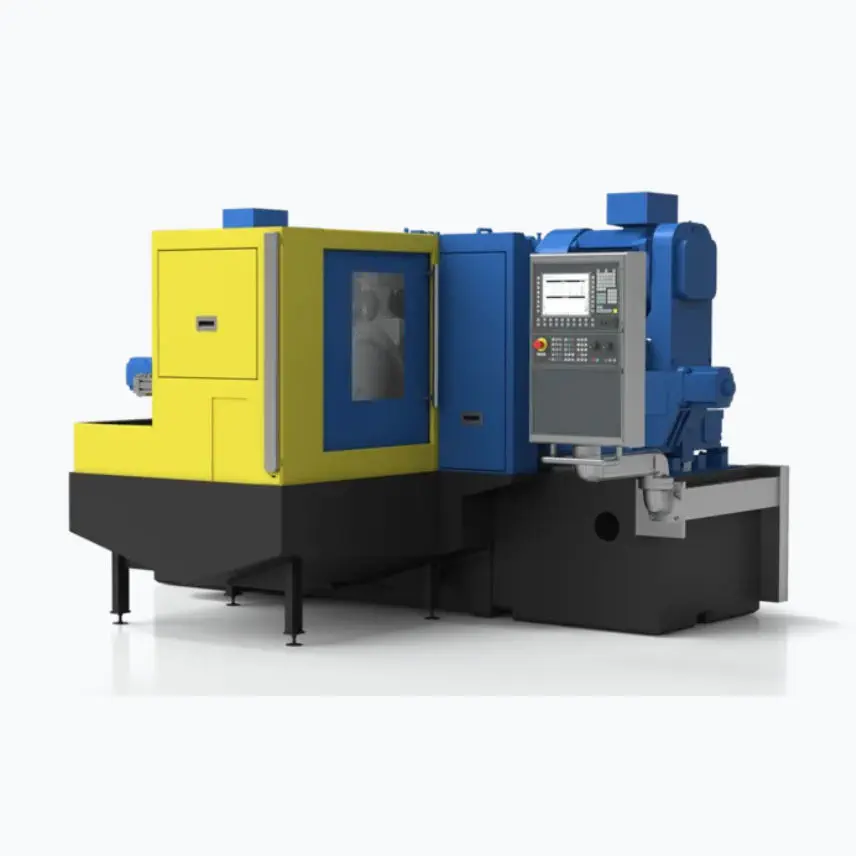

The Lean Selection cam is an economical and flexible machine concept for grinding camshafts in any lot size. The wheelhead can be fitted with up to two high-capacity grinding spindles, and the swiveling B-axis allows parts to be rough and finish-ground in a single clamping set-up. The Lean Selection cam CBN non-cylindrical grinding machine features userfriendly controls, minimal processing times and a high rate of availability.

Highlights

Grinding with CBN grinding wheels

Circumferential speed of 140 m/s

Wheelhead with up to two high-capacity grinding spindles

Fast changeovers

High rate of availability

Minimal auxiliary times

Easy to operate

Wide range of services

Grinding process descriptions

Efficient camshaft production

Performs rough and finish grinding in a single clamping set-up, which saves time and increases accuracy

Design targeted for noncircular grinding, significantly boosting productivity

High rate of utilization with CBN abrasive and oil coolant (emulsion optional)

Proven CBN grinding technology with cutting speeds up to 140 m/s and high feed rates, resulting in fast cycle times

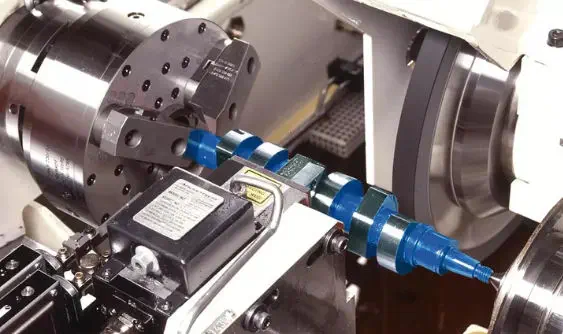

JUNKER 3-point mounting interface for fast changeover and excellent grinding wheel concentricity

High-frequency, high performance grinding spindle (42 kW drive capacity) with extremely low-maintenance thanks to lifetime lubrication and air seal

Ergonomical machine concept with the option of manual loading

Sophisticated, high-tech, user-friendly CNC controls

JUNKER standard bore guarantees maximal accuracy and extremely fast tooling times

The JUNKER standard bore is featured on the wheelhead and workhead and reduces the machine‘s tooling times.

More from Erwin Junker Maschinenfabrik GmbH