Attributes

| Name | Value |

|---|---|

| Type | cylindrical |

| Applications | workpiece, for shaft |

| Control type | CNC |

Description

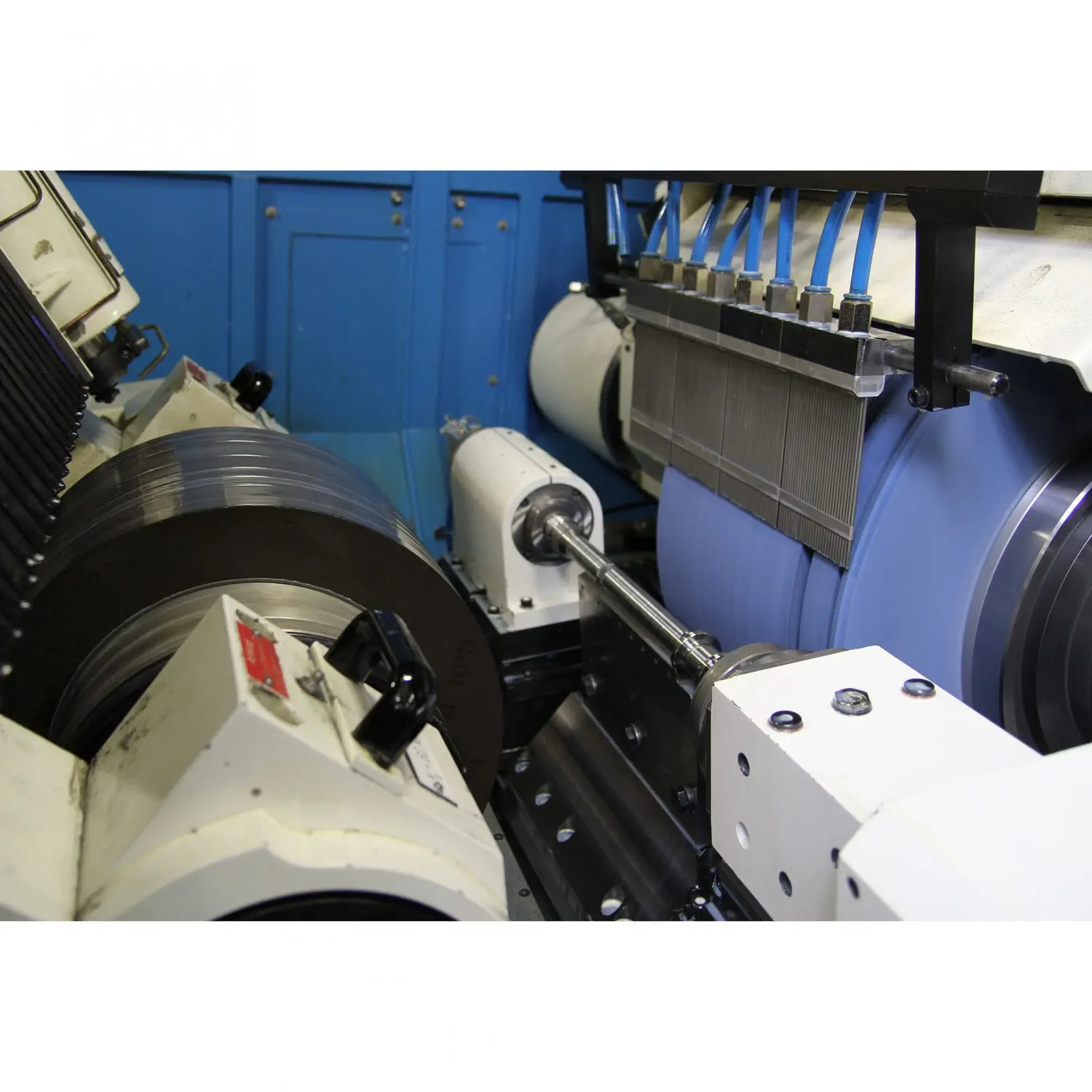

The JUCENTRIC 500 is characterized by extremely short cycle times and outstanding accuracy. The clamping set-up between centers retains the relation to the centerline when grinding shafts and pipes. At the same time, the support rail and regulating wheel guarantee perfect support.

Highlights

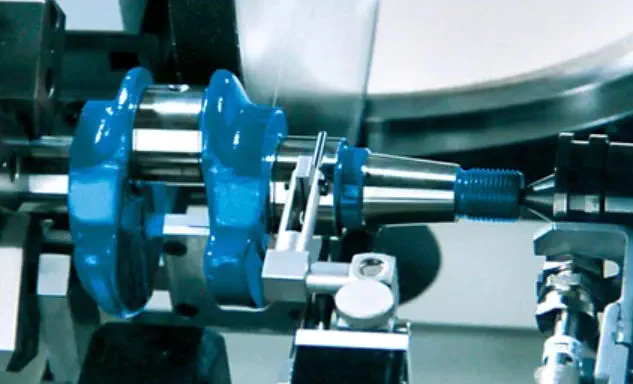

Relation to centerline with clamping set-up between centers

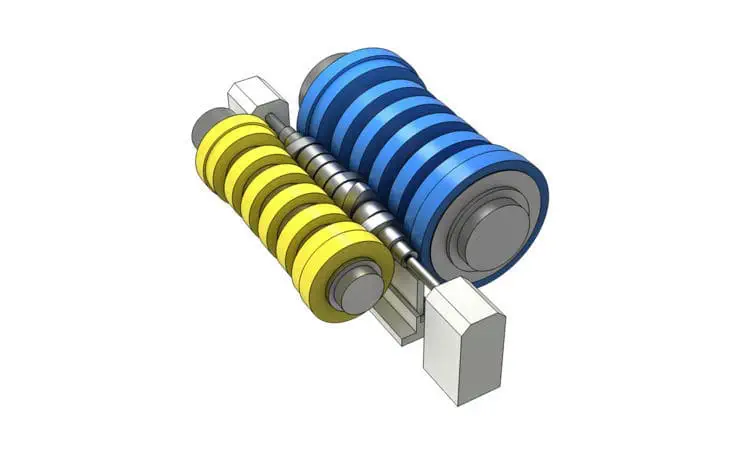

High dimensional accuracy thanks to support by regulating wheel and support rail with patented CNC height adjustment

Shortest cycle times through simultaneous grinding of all diameters

Minimized undulations with grinding wheel balancing on two planes

Extremely low running noise due to grinding spindle with direct drive

Grinding process descriptions

The workpiece is positioned and clamped between centers. Grinding is carried out while clamped; the CNC-controlled support rail, the regulating wheel and the grinding wheel are evenly readjusted until the finished dimension is reached. This unique, ingenious procedure is currently patent pending.

Driving is carried out via a driver on the C-axis of the workhead. Upon the completion of grinding, the grinding gap opens and the workpiece is removed.

Equipment and Options

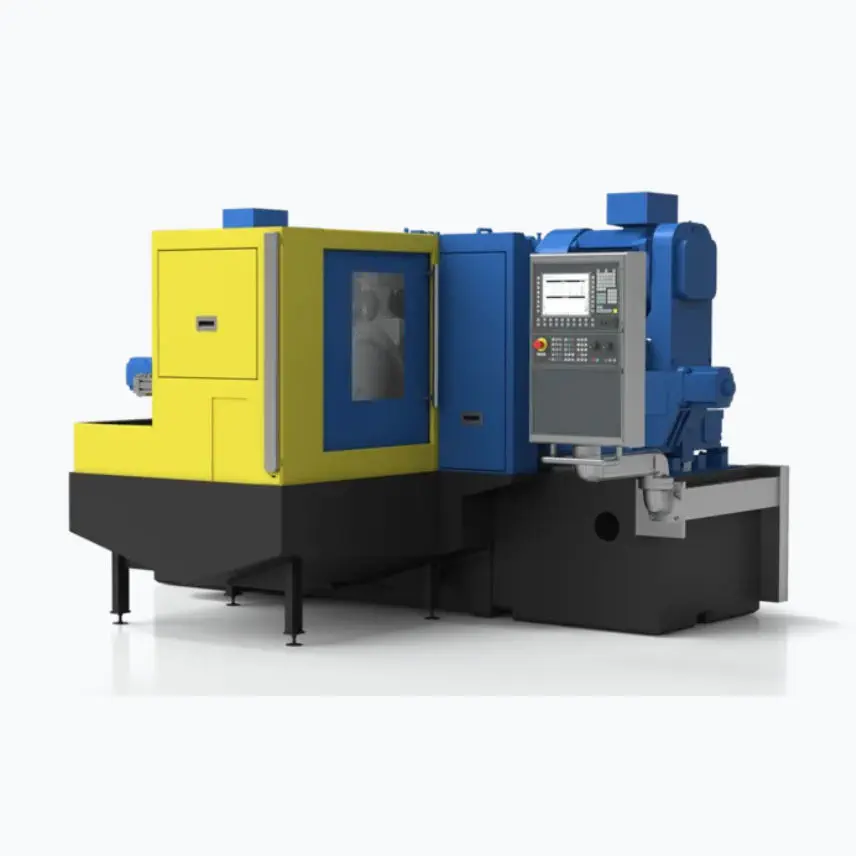

MACHINE BED

The machine bed made of mineral cast provides impressive damping behavior and torsional rigidity. The temperature stability allows fluctuations in the ambient temperature to be compensated with a minimum of effort, ensuring a high level of dimensional stability throughout the whole day.

LOADING SYSTEMS

JUNKER offers both internal and external loading systems for all its machine series, depending on customer and workpiece requirements.

More from Erwin Junker Maschinenfabrik GmbH