Attributes

| Name | Value |

|---|---|

| Applications | workpiece, camshaft |

| Control type | CNC |

| Other characteristics | hydrostatic |

Description

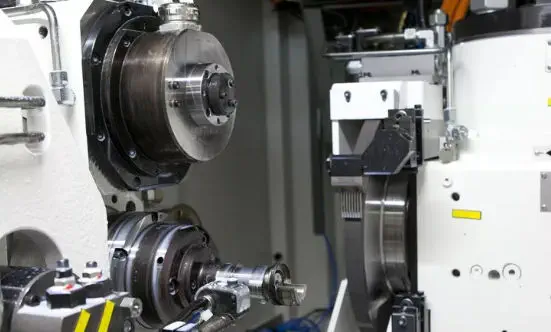

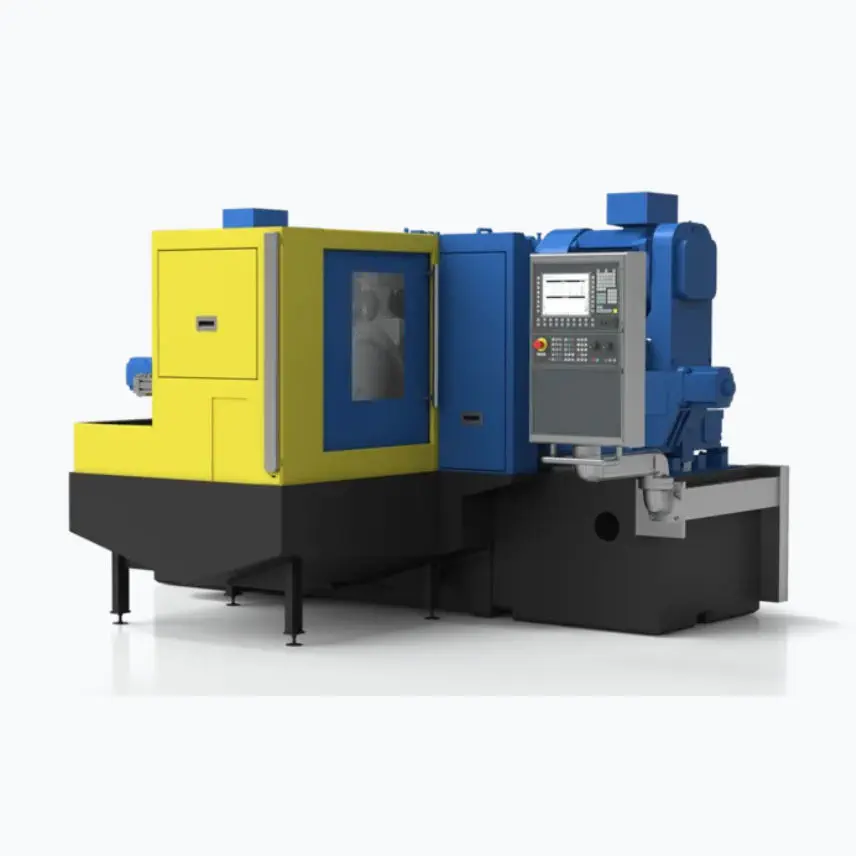

The OD/ID grinding machines of the JUCAM series impress with precise grinding results in a single clamping set-up. Thanks to the control system with learning function – with which virtually all disturbing variables are compensated – camshafts, cam pieces and individual cams are given a perfect finish. The many decades of experience in grinding cams, the many special solutions and the resulting expertise in finding solutions convince engine and pump manufacturers the world over.

Highlights

Broad range of grinding solutions for camshafts, cam pieces and individual cams

Non-cylindrical OD/ID grinding

High utility value through adjustment to respective grinding assignment

High long-term precision due to hydrostatic round guides

Maximum repeat accuracy thanks to CBN or diamond abrasives

Minimized undulations due to grinding wheel balancing on two levels

Grinding process descriptions

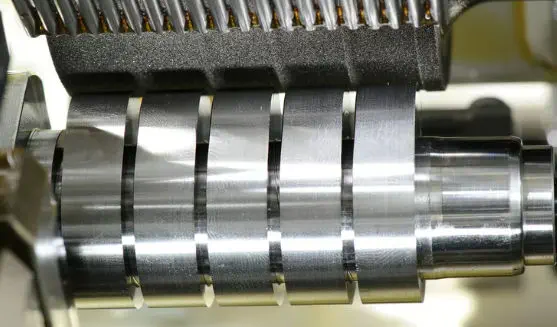

Grinding machines for grinding camshafts, cam pieces and individual cams combine non-cylindrical grinding for the cams and cylindrical grinding for the bearings. With non-cylindrical OD/ID grinding, the grinding wheel follows the cam contour through interpolation of the workpiece spindle (C-axis) with the grinding spindle (X-axis). CBN or diamond are used as an abrasive – for high cutting performance with a constant level of quality and a long tool life.

The cam geometry is specified in a lift table. In the process, each angle is assigned a lift value to define the cam contour and import it to the program. The software then interpolates the values automatically. The cam contour is frequently concave in the infeed and discharge area.

More from Erwin Junker Maschinenfabrik GmbH