Attributes

| Name | Value |

|---|---|

| Type | centerless |

| Applications | workpiece |

| Control type | CNC |

| Other characteristics | high-precision, high-productivity, CBN |

Description

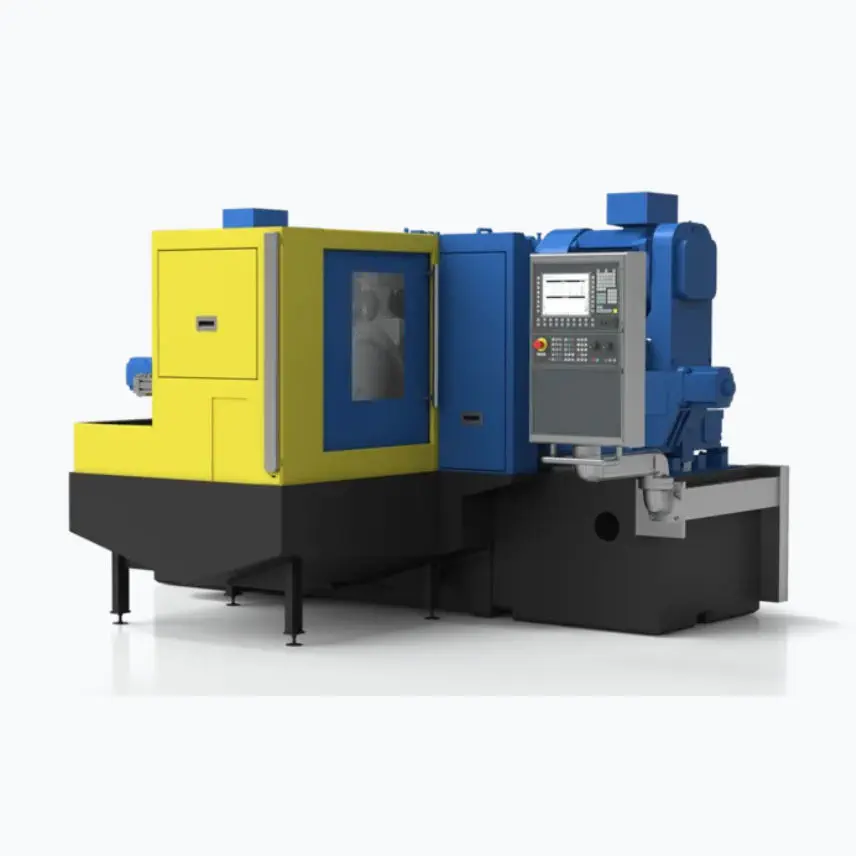

JUPITER series centerless grinding machines offer substantial production benefits: The patented CNC height adjustment of the support blade minimizes tooling times, automatic adjustment of the grinding gap geometry optimizes the grinding process and the inclined bed guarantees maximum dimensional precision. Depending on the application, corundum, CBN or diamond is used as an abrasive.

Highlights

Rapid set-up due to patented CNC height adjustment of the support blade

Minimized undulations with grinding wheel balancing on two planes

Extremely low running noise due to grinding spindle with direct drive

Optimum grinding quality as a result of market-leading rigidity

Optimized grinding process due to automatic grinding gap geometry setting

Individual CNC dressing of grinding wheel and regulating wheel

Grinding process descriptions

During centerless cylindrical grinding, the workpiece is not clamped but lies in the grinding gap between the grinding wheel, regulating wheel and support blade. The grinding pressure presses the workpiece against the regulating wheel, which brakes the workpiece to its own peripheral speed.

For this to work, the friction at the regulating wheel must be greater than the friction at the grinding wheel. The friction is achieved by the rubber bond at the regulating wheel and by inclining the support blade and machine bed.

Throughfeed grinding is among the most productive methods used in the field of grinding technology. It entails workpieces traveling through the machine in a continuous stream without interruption. The grinding wheel has defined roughing, finishing and ultra-fine grinding zones, enabling it to grind all the workpieces to one diameter.

More from Erwin Junker Maschinenfabrik GmbH