Attributes

| Name | Value |

|---|---|

| Applications | for crankshafts |

| Control type | CNC |

| Other characteristics | high-precision, high-productivity |

Description

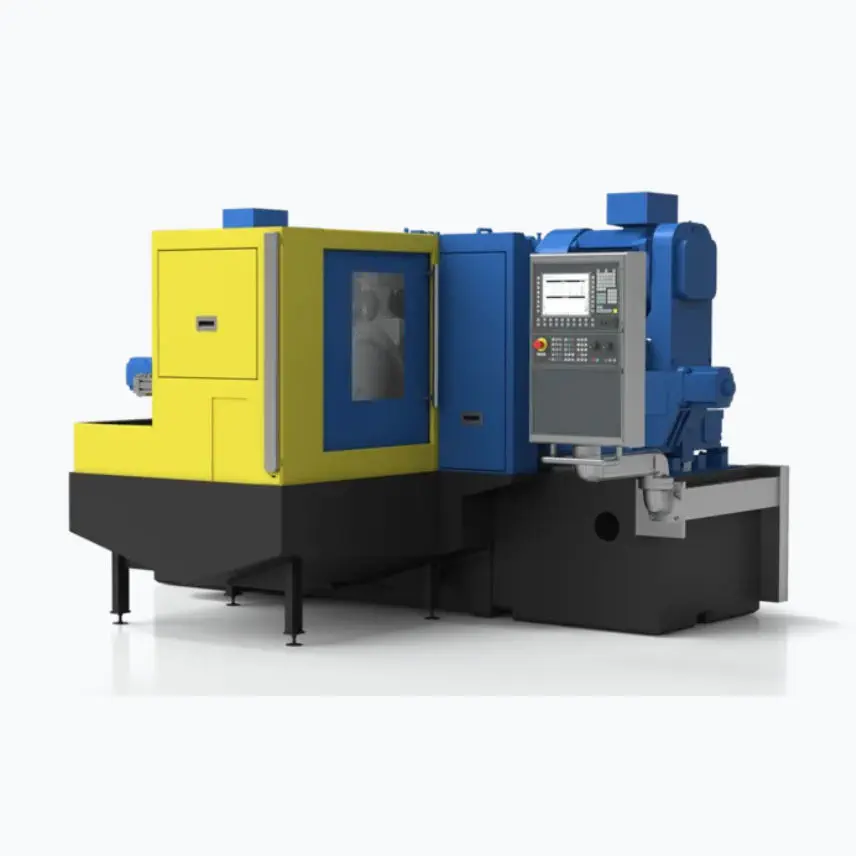

The JUCRANK non-cylindrical grinding machine accomplishes all grinding tasks on crankshafts. Maximum accuracy and quick cycle times are achieved through oscillation grinding in a single clamping set-up and through the productive machine concept. Ideal dimensional stability and high process reliability are ensured through in-process measurements, for example.

Rough and finish grinding of crankshafts in all batch sizes can be carried out on platforms with various dimensions. For main, pin and thrust bearings, diverse geometric shapes as well as plane surfaces and radii can be ground. Internationally renowned engine manufacturers place their trust in the versatile, productive JUCRANK non-cylindrical grinding machine.

Highlights

- High process reliability due to complete grinding in a single set-up

- Optimum grinding quality due to automatic compensation of disturbance variables

- High dimensional stability due to in-process measuring system

- Flexible use for wide-ranging different cylinder numbers by CNC resetting

- Extreme smooth running due to directly driven grinding and work piece spindles

- Optimum support provided with self centering three point steady rests

PENDULUM GRINDING

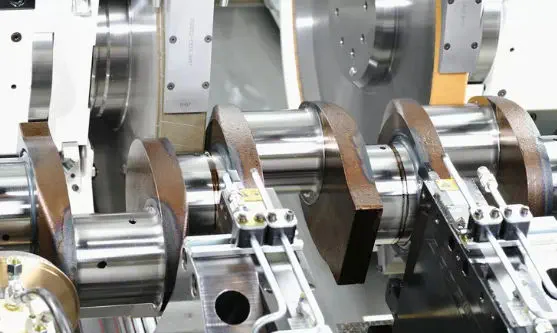

The pendulum grinding method enables crankshafts to be rough and finish ground in a single clamping set-up. The crankshaft rotates around its central axis and the grinding wheel follows the circular motion of the pin bearing by interpolation of the workpiece spindle (C axis) with the grinding spindle (X axis).

To achieve top concentricity quality, crankshafts are frequently supported on a steady.

More from Erwin Junker Maschinenfabrik GmbH