Attributes

| Name | Value |

|---|---|

| Type | cartridge |

| Connexion | G |

| Body | screw-in, manifold |

| Applications | hydraulic, pneumatic |

| Material | stainless steel |

| Other characteristics | pilot-operated |

| Pressure | Min.: 3 bar(43.5 psi)Max.: 230 bar(3,335.9 psi) |

| Temperature | Min.: -30 °C(-22 °F)Max.: 80 °C(176 °F) |

| Flow rate | 14 l/min, 250 l/min(3.7 us gal/min, 66.04 us gal/min) |

Description

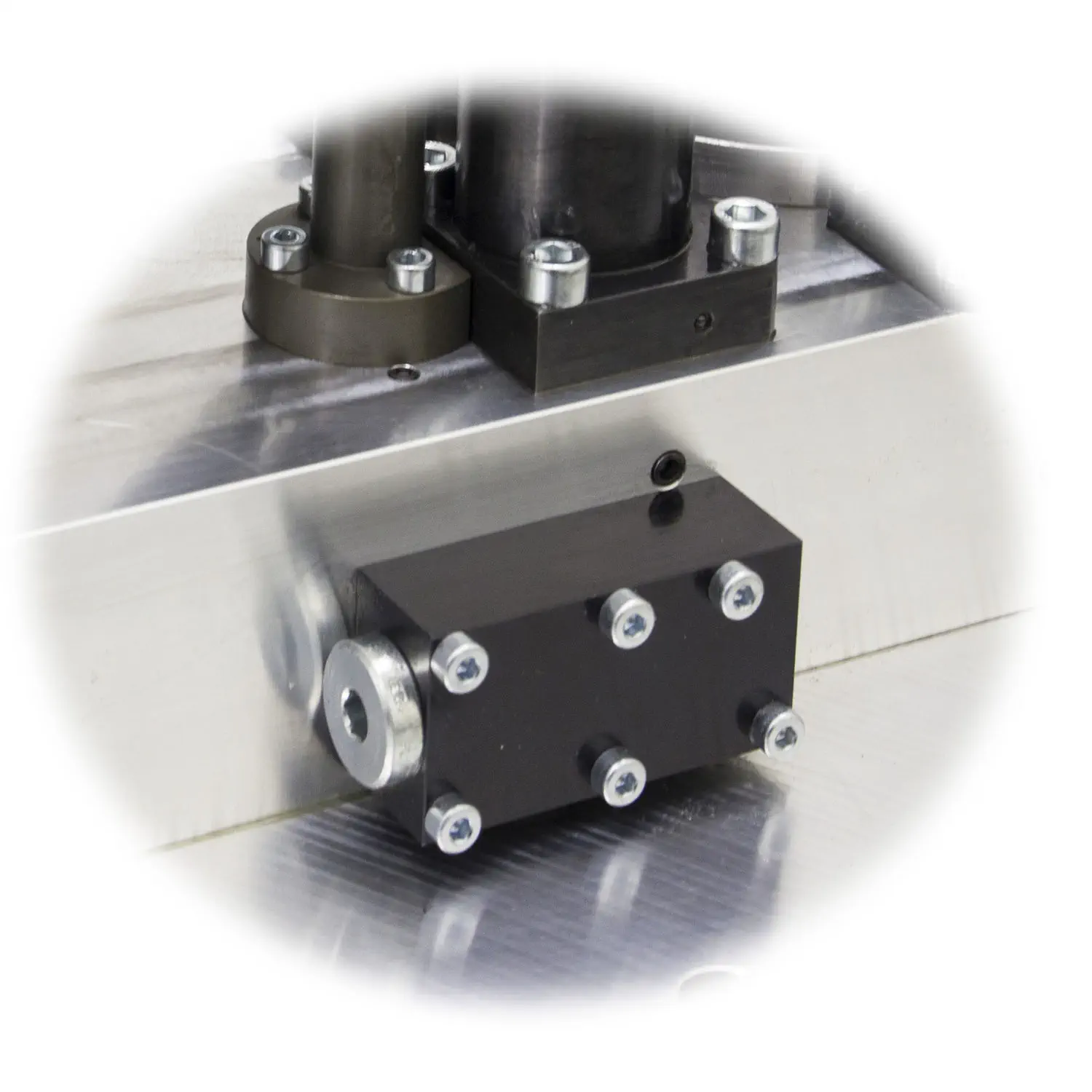

Holding Valve, double check valve

up to 230 BAR, G1/4 OR Manifold type, HYDRAULIC and PNEUMATIC

The valve consists of a one-piece housing and is therefore repeatedly mountable.

– Screw-In and manifold mounting

– Simple counter contour

– Working pressure from 3-230 bar

– Completely sealed

– For hydraulic and pneumatic and other fluides useable

These pilot operated check valves are available in a screw-in

(G1/4) and manifold mounting (flange) version.

The valves block against the screw-in direction ( ). A-> P

What means, when the pressurization is aborded, the set

pressure in the channel is maintained. A

With pilot pressure at , the valve can be opened against the X

reverse direction and the media return from is A->P

guaranteed.

Generally:

The installation dimensions and tolerances must be

observed.

The maximum permissible flow rates should not be

exceeded.

The maximum pressure should not be exceeded even with

pressure peaks. This is especially neccessary for sudden

load in the direction of flow e.g. in accumulator circuits.

Mounting:

The screw-in valve must be completely screwed in until

the stop on the front side.

The insert dimensions must be checked.

The screw-in valve must be mounted with the specified

hexagon socket . WS9

Even in softer materials such as aluminum, both valves

can be used.

More from Inosol