Attributes

| Name | Value |

|---|---|

| Other characteristics | double-acting, abrasion-resistant, corrosion-resistant |

Description

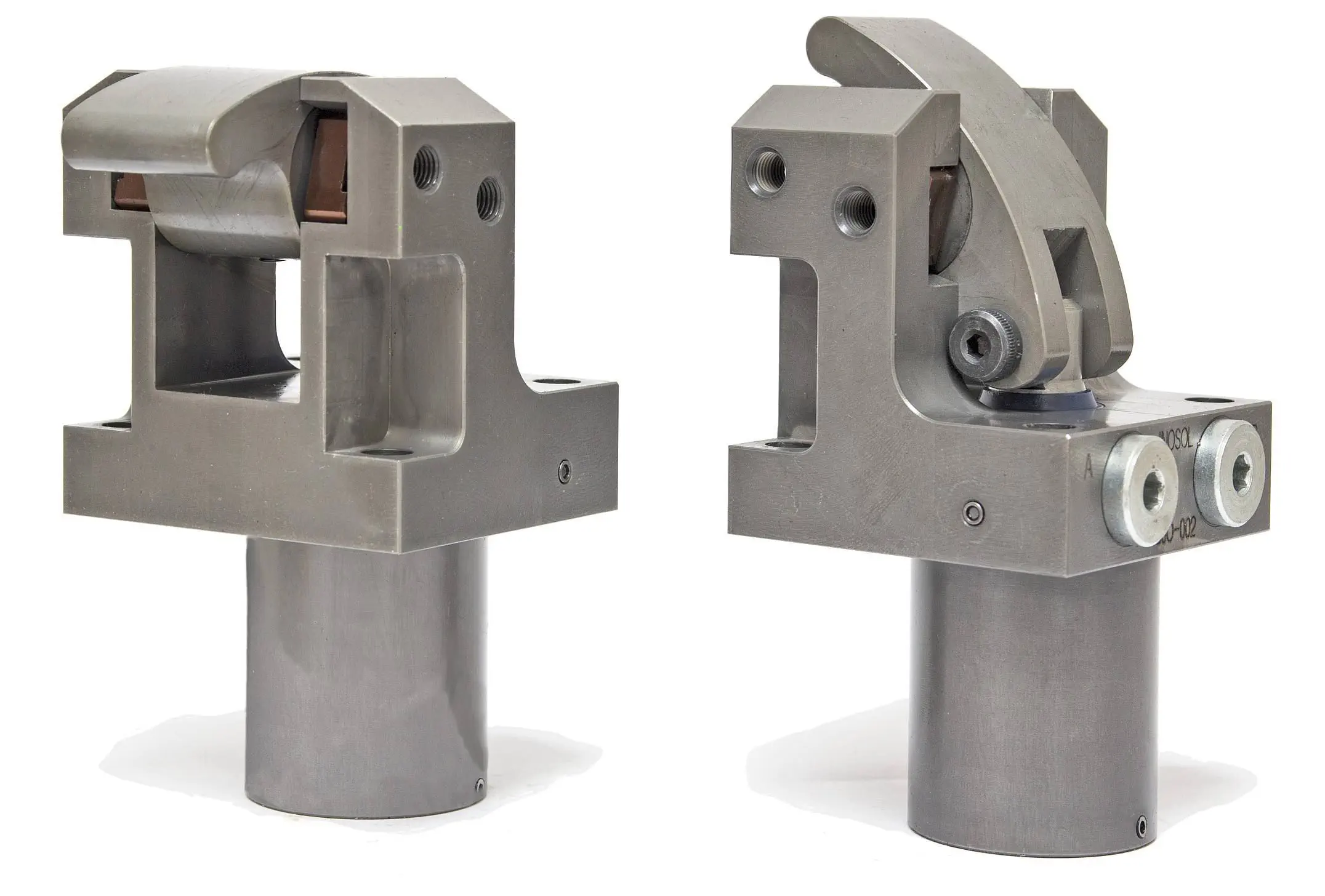

Sliding Joint Clamp, hydraulic, up to 400 bar, double acting

In particular, the clamping cylinder can also be used in the field of mining- and casting operations.

Because of the design of the guides, seals and wipers here is a significantly longer service life reachable, as with comparable other clamping solutions.

– High clamping force

– Solid Design

– For high vibrations or lateral force absorption

– No interference contour while loading the parts

– Oil connection via thread- or manifold connection

– Withstands large dirt

Recommendations for use:

These clamping elements are available in 2 - externally

identical versions.

For the type , lever and housing are almost free ISJC-002

of play in the axial direction of the lever pivot point.

This allows the elements to . absorb high lateral forces

In type , the lever and housing are completely ISJC-004

decoupled from each other.

Here, the lever is held in its middle position by the

integrated disc springs.

This version is suitable . for high vibrations

The Sliding Joint Clamping cylinder has a high clamping

force with a relatively small footprint. For this reason, this

solution is suitable for machines with high performance

and difficult space conditions.

Above all, the clamping cylinder can also be used in the

mining and foundry industry.

Due to the design of the guides, seals and scrapers, a

significantly longer service life is to be achieved here

than with comparable other clamping solutions.

When installing the sliding joint clamping cylinder, the

flange surface should be adjusted to the height of the

workpiece.

The cylinder is suitable for any mounting position.

More from Inosol